Strip Seal, Modular and Finger Expansion Joints

Hennegan and Associates supplies three steel systems – Modular Expansion Joints , Strip Seal Expansion Joints and Fabricated Steel Plate Expansion Joints.

Modular Expansion Joints

D.S. Brown Steelflex® Modular Expansion Joint Systems have gained overwhelming worldwide acceptance for accommodating and sealing large joint movements on bridge structures. By incorporating the results of recent research activities, each joint system is designed to provide watertight, fatigue resistant, long-term, maintenance-free performance.

Modular Expansion Joint Systems:

Design Principles

Fatigue Resistant

Modular expansion joint assemblies are subjected to millions of high dynamic stress cycles due to passing vehicle loads. Recognizing the significance of these dynamic loads on the long-term performance of expansion joint systems, D.S. Brown became the first North American company to introduce fatigue-resistant design principles to modular expansion joint assemblies. It is strongly recommended that a specification which includes fatigue design provisions be included in the contract documents.

Modular expansion joint assemblies are subjected to millions of high dynamic stress cycles due to passing vehicle loads. Recognizing the significance of these dynamic loads on the long-term performance of expansion joint systems, D.S. Brown became the first North American company to introduce fatigue-resistant design principles to modular expansion joint assemblies. It is strongly recommended that a specification which includes fatigue design provisions be included in the contract documents.

Watertight Integrity

Each Steelflex® Modular Expansion Joint System not only bridges the joint gap but also protects the structure from premature corrosion. Design of the strip seal sealing element is based on compression of the neoprene seal lug into the gland recess of the centerbeam and edge beam. This mechanically-locked neoprene seal not only provides excellent watertight characteristics but also achieves high pullout resistance.

Datasheet: Joint Selection & Design Data (PDF)

Strip Seal Expansion Joints

For decades, cast-in-place Steelflex® Strip Seal Expansion Joint System’s have provided superior watertight performance and longevity over bolt-down, segmental and pourable expansion joint systems. Because of this proven performance, Steelflex® Strip Seal Expansion Joint Systems have become the overwhelming choice of owners and specifying engineers around the world for accommodating up to five inches(127mm) of total structural movement.

For decades, cast-in-place Steelflex® Strip Seal Expansion Joint System’s have provided superior watertight performance and longevity over bolt-down, segmental and pourable expansion joint systems. Because of this proven performance, Steelflex® Strip Seal Expansion Joint Systems have become the overwhelming choice of owners and specifying engineers around the world for accommodating up to five inches(127mm) of total structural movement.

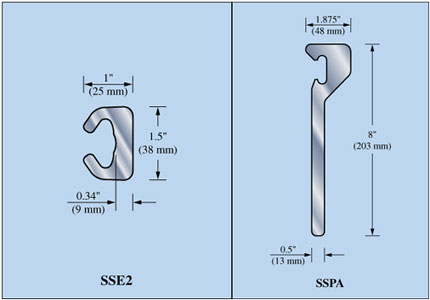

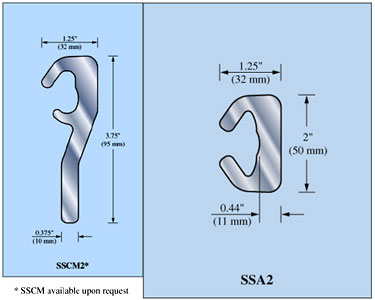

Steelflex® Rail Profiles:

Steelflex® rail profiles are one-piece construction, manufactured using innovative hot rolled/non-machined and hot rolled/machined technology. All proprietary steel rails are available in ASTM A36 or ASTM A588 steel grades.

Because it is field-proven, the Steelflex® SSCM2 rail profile has become widely accepted worldwide as an economical standard in the industry. Other proprietary steel profiles are available to satisfy your specific project needs.

Steelflex® Neoprene Sealing Elements

Datasheet: Neoprene Gland Selection Chart (PDF)

Finger Joints

Fabricated steel plate expansion joint systems, such as finger joint assemblies and sliding plate and armor joint systems, are still specified on many bridge projects due to proven long-term structural performance. These joint systems are also convenient to install on bridge rehabilitation projects requiring a shallow joint depth and/or staged construction.

Fabricated steel plate expansion joint systems, such as finger joint assemblies and sliding plate and armor joint systems, are still specified on many bridge projects due to proven long-term structural performance. These joint systems are also convenient to install on bridge rehabilitation projects requiring a shallow joint depth and/or staged construction.